Taiwan Tech joins Taiwan Hardware Show to showcase cutting-edge manufacturing technologies in collaboration with metal additive manufacturing technology alliance.

"The Taiwan Hardware Show" is scheduled to take place at the Nangang Exhibition Center from October 18 to 20, 2023. Taiwan Tech has been invited to participate as part of an initiative to deepen collaboration and engagement between academia and industry, showcasing the latest manufacturing processes, products, and applications. This active involvement aims to showcase Taiwan's substantial capabilities on the international stage. Assistant Professor Chih-Hua Hsieh from Taiwan Tech's Taiwan High-Speed 3D Printing Research Center has also been invited to discuss metal additive manufacturing techniques and applications during the exhibition.

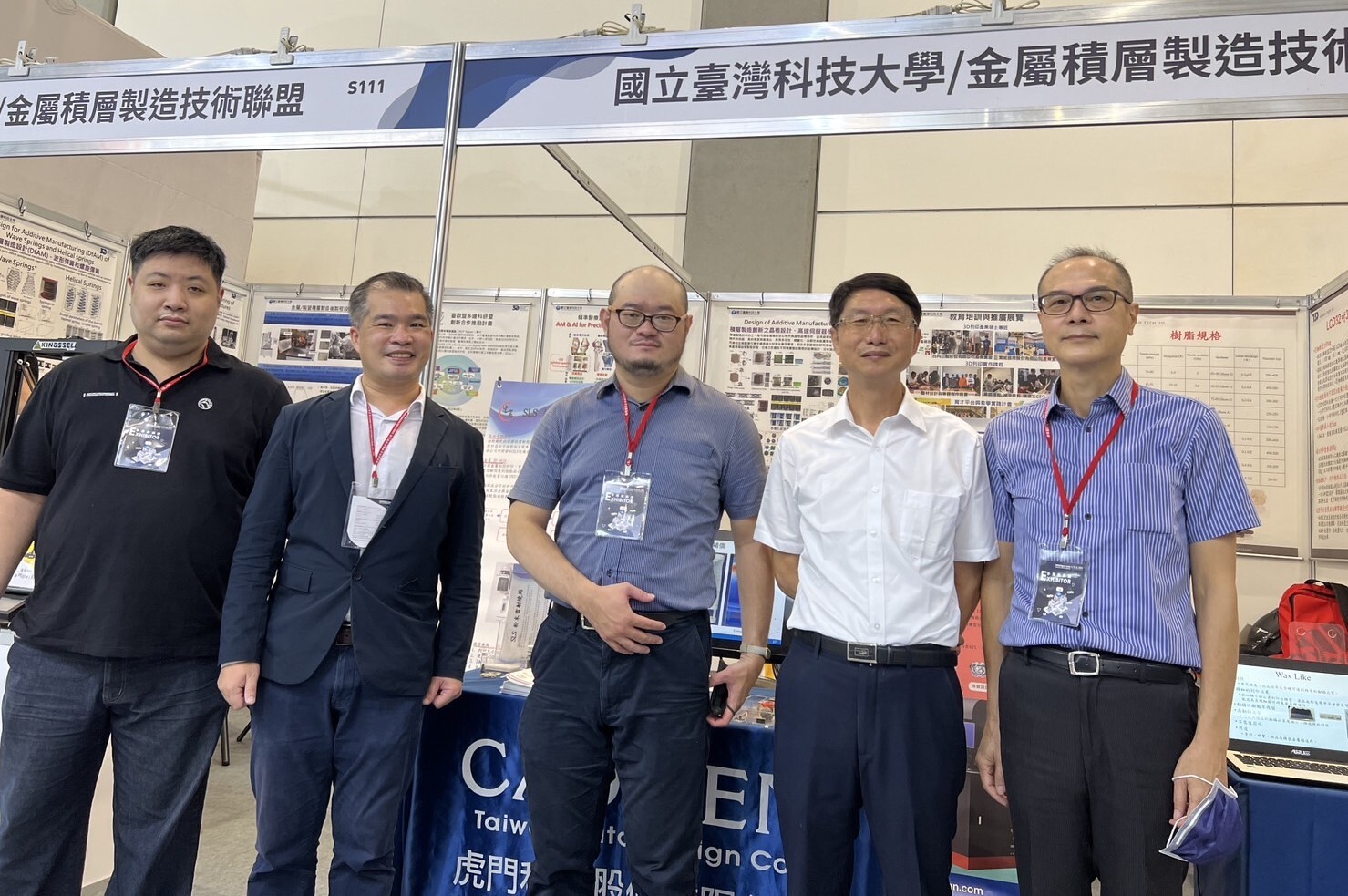

In collaboration with the Metal Additive Manufacturing Technology Alliance, Taiwan Tech's Taiwan High-Speed 3D Printing Research Center will participate in the Taiwan Hardware Show. Noteworthy members of the alliance from left to right include Wei Lu, CEO of Deer Country Technology Co., Ltd.; Dr. Jui-Tang Tsai from Taiwan Auto Design Co (TADC); Assistant Professor Chih-Hua Hsieh from Taiwan Tech; Fu Wen-Chi, General Manager of Kingtec Technical Co., Ltd.; and Ming-Cheng Huang, CEO of Taiwan Tech 3d Co., Ltd.).

This year, the Taiwan Hardware Show relocated to Taipei marking its first expansion since the pandemic. It includes four major themes: "Metal Materials," "Precision Processing Equipment," "Hardware," and "Industrial and Occupational Safety." Together, these themes provide a platform for the industry to explore the latest technological trends. Additionally, the event will also feature activities such as "Industry Forums," "VR Digital Technology," "New Product Launches," "Design Competitions," and "DIY," allowing exhibitors and attendees to share the latest industry insights and technologies.

Chairman Kai-Guo Dai of Kaigo Co., Ltd., the organizing company, mentioned notable international participation with delegations, including Japan, Malaysia, Singapore, Indonesia, Germany, and the United States this year. Additionally, nearly 15 DIY, hand tools, fastener, and hardware buyer groups are coming to Taiwan to explore potential collaborations. Notable participants include the "European DIY Retail Association/Global Home Improvement Network," "Malaysian Chamber of Commerce and Industry for Hardware, Machinery, and Building Materials," and "Japan DIY Home Center Association." Chairman Dai also expressed anticipation for collaboration with Taiwan Tech, offering novel metal manufacturing technologies and related applications at the exhibition, fostering greater opportunities for collaboration and interaction within the academia and industry.

Assistant Professor Chih-Hua Hsieh from Taiwan Tech's Taiwan High-Speed 3D Printing Research Center expressed the center's aspiration to integrate advanced 3D printing manufacturing technologies and materials. Their objective is to develop rapid customization and mass production technologies that combine high speed with precision. This year, they established the Metal Additive Manufacturing Technology Alliance to assist in integrating metal and plastic additive manufacturing technologies, fostering collaboration and knowledge exchange among industry, academia, government, and research institutions.

Taiwan Tech has also invited Taiwan Auto Design Co (TADC) and General Integration Technology to join in the collaborative display for this exhibition. Chung-Nan Ji, General Manager of General Integration Technology, pointed out that Selective Laser Melting (SLM) metal 3D printing technology has significant advantages in the hardware and metal manufacturing industries. SLM equipment offers high precision and rapid production capabilities, reducing costs in the research and production phases, supporting customized production, and addressing small to medium-batch requirements.

Taiwan Auto Design Co (TADC) will showcase the latest in metal 3D printing equipment and samples, particularly focusing on metal complex waterway molds that cannot be produced using traditional equipment.

General Integration Technology will exhibit Selective Laser Melting (SLM) metal 3D printing technology, which enhances design flexibility, production efficiency, and material performance. This technology finds applications in the production and manufacturing of aerospace components. Image credit: General Integration Technology.

Dr. Jui-Tang Tsai from Taiwan Auto Design Co (TADC) emphasized that additive manufacturing in producing metal components significantly differs from traditional subtractive manufacturing processes. It offers greater design flexibility, allowing for innovative designs. During the exhibition, they will employ the ANSYS simulation software for metal additive manufacturing analysis and showcase molds of metal complex waterways produced using SLM technology.

The active involvement of Taiwan Tech in collaboration with the industry not only highlights Taiwan's research capabilities but also elevates its international visibility and influence. This initiative aims to create more opportunities for international academic, industrial, and research exchanges and collaborations.

The Taiwan Metal Materials and Precision Processing Equipment Exhibition, Taiwan Hardware Show, and Industrial and Occupational Safety Exhibition will occur from October 18 to October 20.

For further details regarding the showcased items and conference schedule for the 2023 Taiwan Hardware Show, please refer to the event's official website.